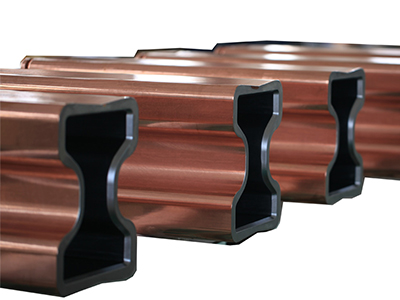

Copper Mold Tubes are the most essential part of a Continuous Casting Machine. Their function is to receive the molten steel and to allow rapid heat transfer and enable quick solidification and guarantee that the acquired billet, bloom, and slab is with enough thick shell. This is thanks to Copper’s excellent thermal conductivity and resistance to thermal erosion and distortion from thermal stress as well as Cost Effectiveness. Copper Molds play a crucial role in increasing continuous efficiency as well as improving steel quality.

Copper Mold Tubes

Copper Molds are usually used in these sizes:

۱۵۰ mm * 150 mm, 125 mm * 125 mm, 120 mm * 120 mm, 100 mm * 100 mm, 80 mm * 80 mm

۱۵۰ mm * 150 mm, 125 mm * 125 mm, 120 mm * 120 mm, 100 mm * 100 mm, 80 mm * 80 mm

Copper Mold Tubes

Chemical Analysis

| Chemical Composition | |

|---|---|

| SF-Cu = TP2 = DHP | |

| DIN 1787 | Grade |

| 99.96< | Cu% |

| 0.015% ~ 0.040 | P % |