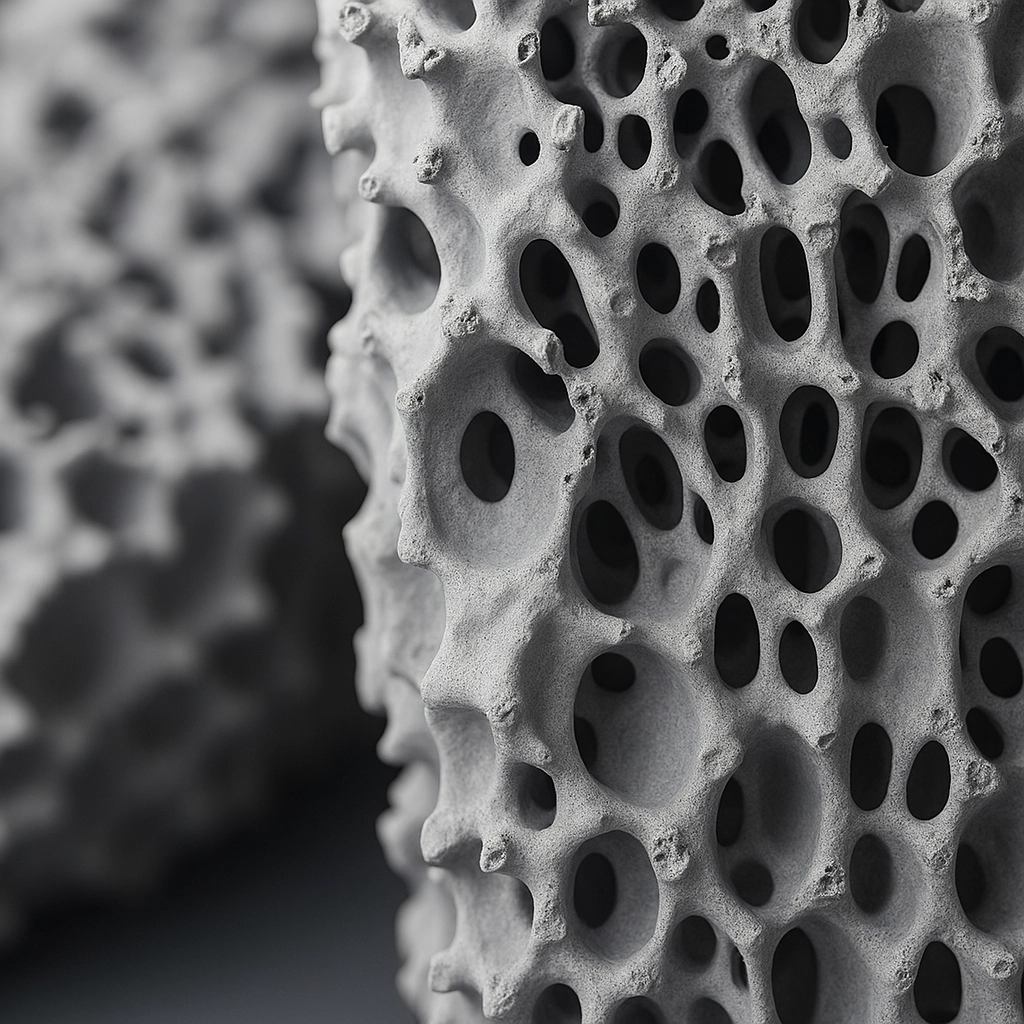

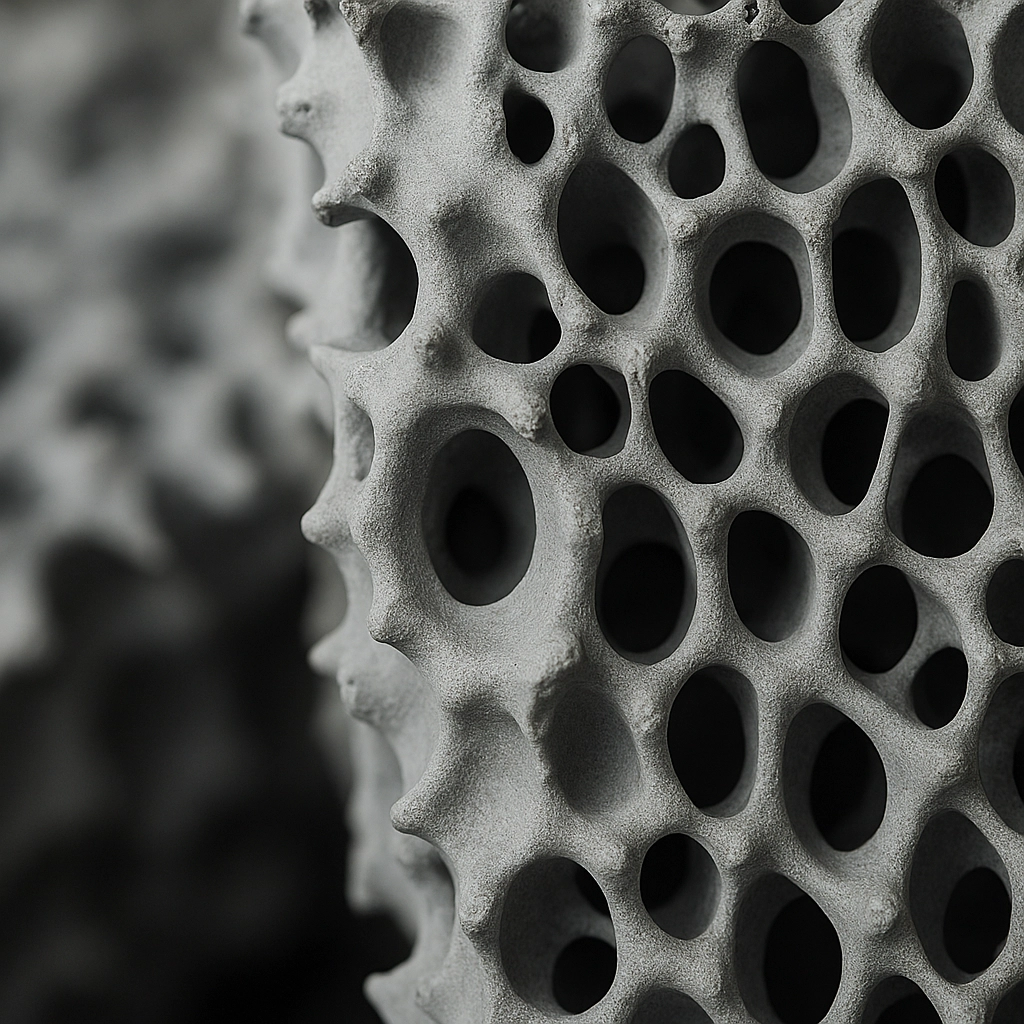

Ceramic foam filters are an advanced technology designed to deliver clean, impurity-free molten metal. Their intelligent network structure not only controls the turbulence of flow but also traps inclusions, preventing them from entering the mould.

With our specialized solutions for steel, cast iron, and non-ferrous alloys, we help you reduce defects, improve surface quality, and enhance the structural integrity of the final product.

A smart choice for flawless production and higher profitability.

In the precise world of casting, quality is never a coincidence. Our ceramic foam filters act as the final gatekeeper to ensure the purity of your molten metal. With their engineered network structure, they streamline the flow and capture even the finest impurities, preventing structural and surface defects.

The result? A product with flawless finish, reliable mechanical properties, and near-zero waste.

With our filtration solutions, you can elevate your production process to a new level of confidence and efficiency.

Porous ceramic filters play a critical role in the casting industry by purifying molten metal from slag and impurities, ensuring the final quality of the cast component. The performance of these filters is measured by the PPI index (pores per linear inch); a higher PPI value indicates finer pores, which increases the filtration efficiency for removing smaller inclusions.

The choice of filter material depends entirely on the type of molten metal:

For steels: high-temperature resistant filters with a zirconia base

For cast irons: filters with a silicon carbide base

For non-ferrous metals such as aluminum, magnesium, and zinc: filters with an alumina base

Each of these types is available in a wide range of PPI values to meet the specific requirements of each casting process, ensuring the production of flawless, high-quality components.

Porous ceramic foam filters, with their engineered three-dimensional structure, play a crucial role in enhancing casting quality. These filters effectively convert turbulent molten metal flow into a calm, laminar flow, separating non-metallic inclusions and preventing them from entering the mold cavity. This action significantly reduces casting defects, improves mechanical properties, and enhances the surface quality of the final product.

Our company offers filters with specialised bases—zirconia, silicon carbide, and alumina—covering all filtration needs for steel, cast iron, and non-ferrous metals. Our technical team provides expert consultation to help you select the optimal PPI for achieving the best results.

With a commitment to superior quality, on-time delivery, and competitive pricing, we are a reliable partner for optimising your production process and minimising waste. Ensure the quality of your castings with us.

| Dimension (mm) | Shape |

|---|---|

| 50×50×22 / 40×40×22 | Square |

| 50×30×22 / 50×75×22 / 50×100×22 | Rectangle |

| 10, 15, 20 | Pore Size (ppi) |

WhatsApp us