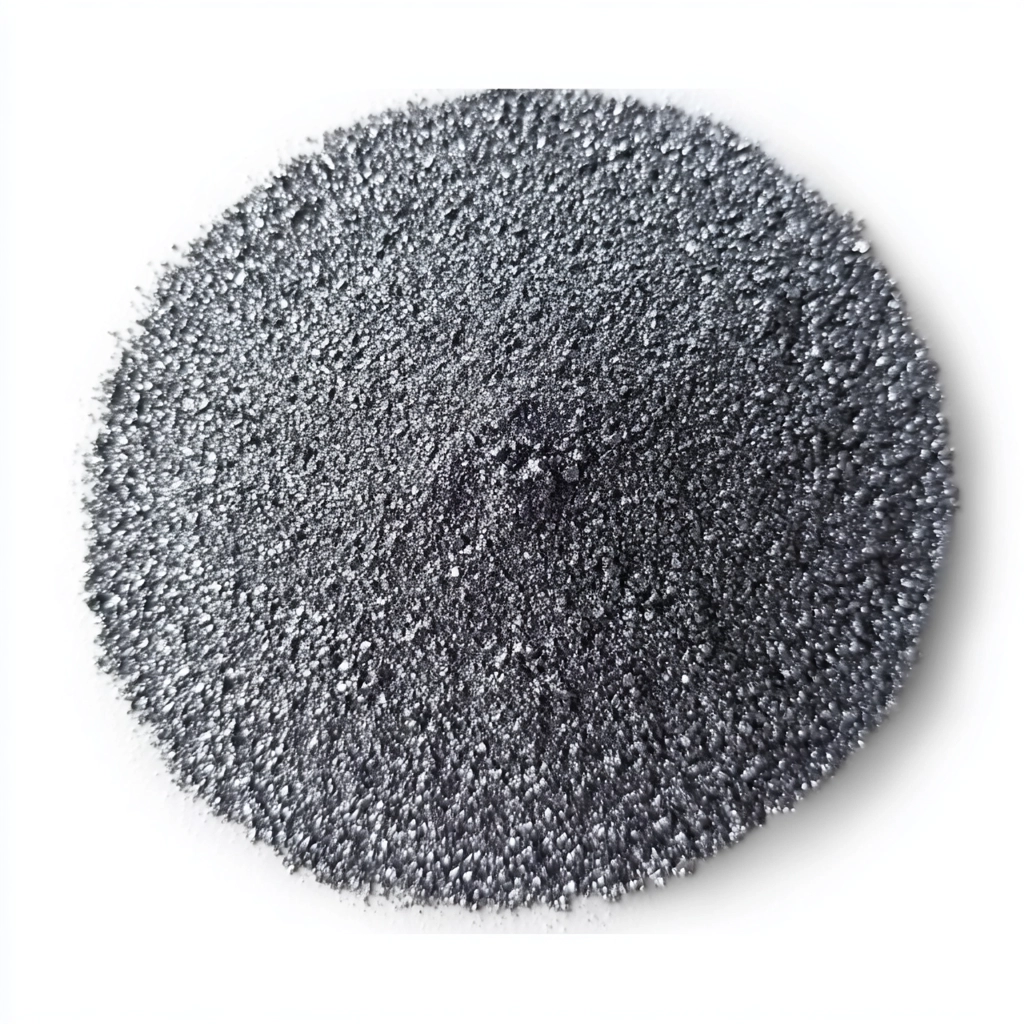

The inoculant superseed is an essential material in the casting of aluminium and copper alloys, promoting uniform grain refinement and a homogeneous structure by generating numerous crystal nuclei. Its precise chemical composition enhances the mechanical properties of the alloy, increasing the strength and durability of components. The superseed’s high thermal stability and controlled reactivity ensure reliable performance at the high temperatures of the casting process. Additionally, using this inoculant in industrial production improves casting efficiency and enhances the surface quality of the components.

The inoculant superseed, with its advanced formulation and combination of active elements, plays a key role in improving the solidification process of non-ferrous alloys. By increasing nucleation sites, it refines the final alloy structure and enhances mechanical properties such as strength, toughness, and wear resistance. Its excellent stability under severe thermal conditions ensures consistent performance even in long-duration processes. Using the superseed reduces solidification defects such as porosity and segregation, significantly improving surface quality and uniformity, thereby elevating overall production efficiency.

In the metallurgy industry, inoculants are used as key materials to improve the mechanical and structural properties of alloys. The use of inoculants in aluminum and copper alloys refines the crystalline structure, thereby enhancing the strength, ductility, and physical properties of the alloy. This process, by generating numerous small crystal nuclei, limits the growth of coarse grains and creates a uniform and homogeneous structure.

Additionally, non-metallic modifiers play an important role in altering and improving the eutectic structure of aluminium alloys. These modifiers, by changing the phase composition and controlling the crystallisation process, enhance wear resistance, extend component lifespan, and optimise final properties. The combined use of inoculants and modifiers provides an effective solution for producing high-quality alloys with superior performance, suitable for advanced industries such as aerospace, automotive, and industrial equipment.

The inoculant superseed, with its special composition and ability to generate numerous crystal nuclei, not only improves the microscopic structure but also promotes effective grain refinement in aluminium and copper alloys. This feature enhances the strength, uniformity, and durability of components under demanding operating conditions. Its high thermal stability and controlled reactivity make the superseed an ideal choice for high-quality, long-lasting production.

Our company provides superseed inoculants manufactured from premium raw materials using advanced technology, serving as a reliable partner for customers aiming to enhance their products. Our expert team ensures that all products comply with international standards. Additionally, timely delivery, precise technical consultation, and competitive pricing make us a preferred choice for manufacturers and foundries. The inoculant superseed is a dependable step toward improved efficiency, higher quality, and reduced production costs in non-ferrous metal industries.

| Size | Sr | Ca | Al | Si |

|---|---|---|---|---|

| 0.2–0.7 mm, 2–7 mm | 0.87% | 0.084% | 0.24% | 74.78% |

WhatsApp us