Steel beams are among the primary structural steel sections used in building construction and metal structures. Known as the backbone of steel frameworks, they provide high resistance to bending and heavy loads. These sections are typically produced in I or H shapes to maximise strength and stability while minimising steel consumption.

Beams are classified according to various standards, such as IPE (European), IPN/INP (Chinese and Russian), and HEB/HEA (wide flange). Each standard has specific dimensional and mechanical properties, and the choice depends on the type of structure and the applied loads.

Steel beams are manufactured through hot rolling of steel billets in steel mills, ensuring precise section shapes and stable mechanical properties.

Applications include multi-story building frameworks, bridges, industrial structures, warehouses, and large civil engineering projects. Due to their critical role in structural safety, selecting the appropriate size and type of beam according to engineering calculations and technical considerations is essential.

In many projects, steel beams, along with bolted or welded connections, braces, and secondary beams, form a reliable and stable load-bearing system.

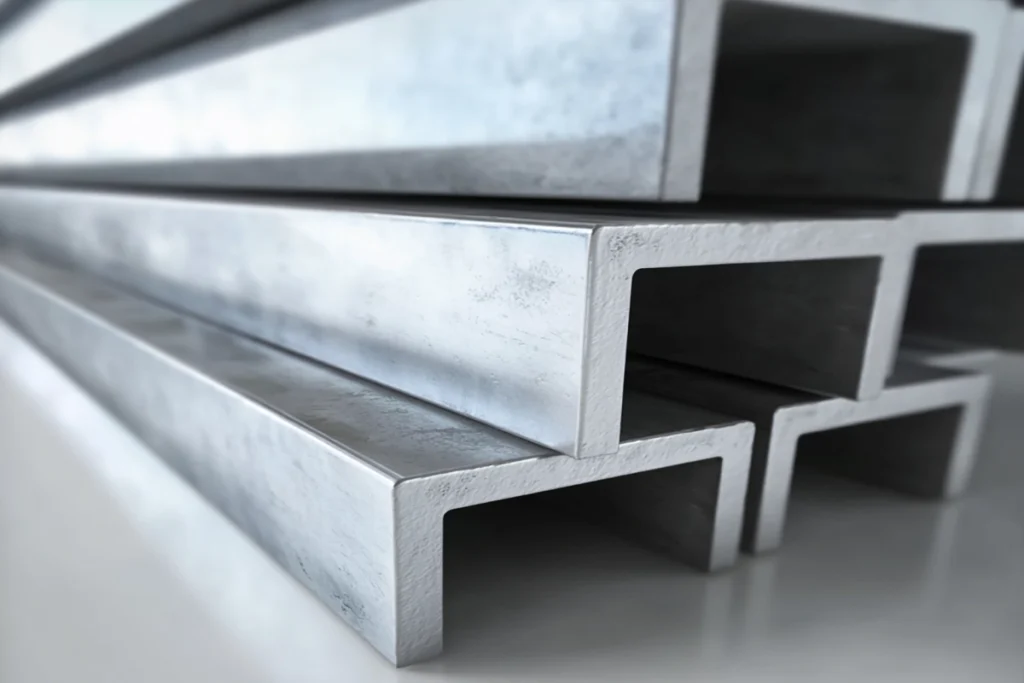

Channels are one of the widely used steel sections, typically produced in U shape or sometimes C shape, with vertical walls (flanges) perpendicular to the base or web. This design provides good performance under bending and compressive forces, while also allowing easy bolted or welded connections.

Channels are manufactured in two types: pressed (sheet-formed) and fabricated (directly from hot-rolled steel billets), according to standards such as UNP or UPE. The main differences lie in flange thickness and edge shape.

Applications of this steel section are diverse: from constructing frames or skeletons of machinery and industrial equipment, to trusses, heavy-duty racks, large doors, trailer chassis, and civil structures including warehouses. Their ease of cutting, drilling, and welding makes channels a reliable choice in both small and large projects.

Selecting the appropriate channel size depends on load capacity, section standards, and environmental conditions. For corrosion resistance, galvanized or coated channels can be used to extend the service life of the structure.

Angles are among the most commonly used steel sections, produced in an L-shape consisting of two perpendicular legs. These legs can be of equal length (equal angles) or different lengths (unequal angles). Their simple and robust design makes angles widely used in metal connections, bracing, and framework construction.

Angles are manufactured through hot rolling (fabricated) or sheet steel forming (pressed) methods. Fabricated angles are often preferred in heavy projects due to their dimensional uniformity and stable mechanical properties.

The applications of angles are highly diverse: construction of columns, trusses, metal racks, industrial platforms, metal structures, braces, bridges, and warehouse frameworks. They are also used in lighter projects, such as large window frames or temporary structures.

Due to their high bending, shear, and compressive strength, as well as easy welding and assembly, angles are a staple in any construction or industrial workshop. For enhanced corrosion resistance, galvanized or coated angles are commonly used.

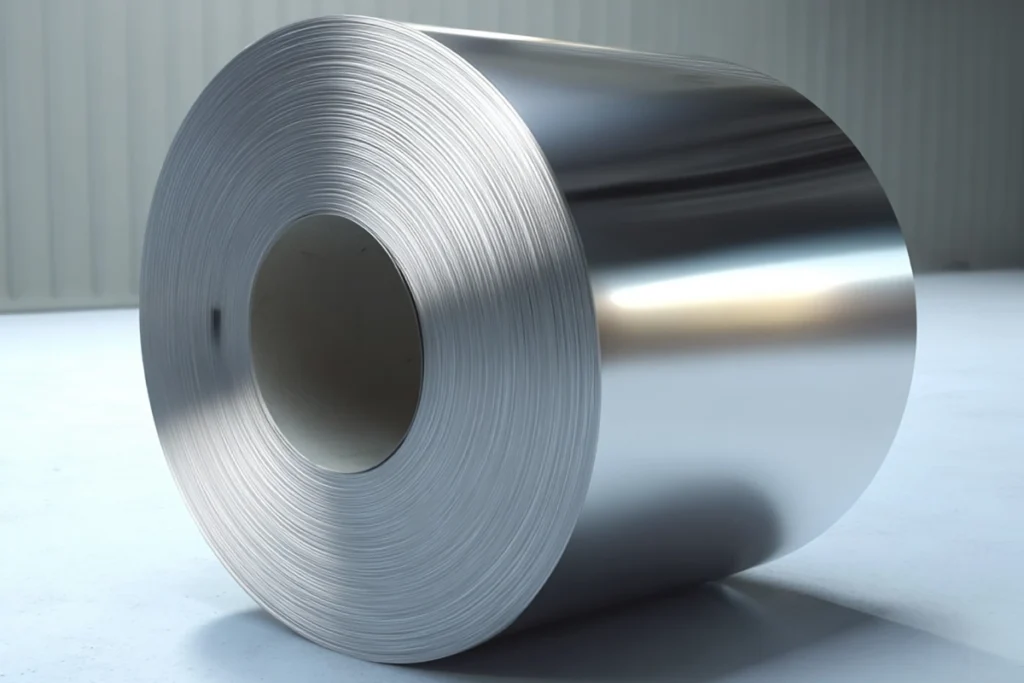

Steel sheets, also known as steel plates, are among the most widely used products of hot-rolled or cold-rolled processes, produced in various thicknesses and dimensions. Their primary raw material is typically steel slabs, which are rolled into smooth, flat sheets.

Based on the manufacturing process, steel sheets are divided into hot-rolled (black sheet) and cold-rolled (oiled sheet) categories. Hot-rolled sheets have a relatively rough surface and dark color and are used in structural, industrial, and construction applications. Cold-rolled sheets, on the other hand, have a smooth, glossy surface and are mainly used in the automotive, home appliance, and component manufacturing industries.

In terms of material and mechanical properties, sheets can also be standard, wear-resistant, galvanized, coated, or stainless steel. Galvanization with a zinc (Zn) layer prevents corrosion and extends product life.

The applications of steel sheets are extensive, including vehicle bodies, tanks, industrial equipment, metal furniture, construction structures, and the production of pipes and profiles. Selecting the appropriate thickness, coating, and grade depends on environmental conditions, load requirements, and project type.

labs are steel semi-finished products produced from molten steel through continuous casting or mold casting, shaped as thick rectangular pieces with wide widths and flat surfaces. Typical slab dimensions range from 100 to 250 mm in thickness, 600 to 2200 mm in width, and several meters in length.

As a fundamental product, slabs serve as the primary raw material for hot-rolled sheets (black sheets, galvanized sheets, coated sheets, tin-plated sheets). The surface quality, chemical composition, and structural uniformity of the slab directly affect the quality of the final sheet.

The production process usually begins with melting iron ore or scrap metal in a blast furnace or electric arc furnace, after which the molten steel is directed to a continuous casting machine. Once cooled, the slabs are cut and sorted.

The applications of slabs vary depending on the steel type: carbon steels for construction and structural purposes, alloy steels for automotive, shipbuilding, and pressure equipment industries. To enhance durability, some slabs undergo heat treatment or surface conditioning before rolling.

Alloy steel is a type of steel that, in addition to carbon, is strengthened by adding alloying elements such as chromium, nickel, manganese, molybdenum, vanadium, or tungsten. These elements can be added individually or in combination to enhance strength, hardness, wear resistance, corrosion resistance, or heat resistance.

Based on the type and amount of added elements, alloy steel is classified into two main groups: low-alloy and high-alloy steels. Low-alloy steels typically contain less than 8% alloying elements and are mainly used in general structures, automotive components, and pipelines. High-alloy steels, containing higher percentages of alloying elements, are used for specialized applications such as stainless steel, cutting tools, and heat-resistant components in the oil, gas, and aerospace industries.

The production of alloy steel requires precise control of chemical composition, melting temperature, and heat treatment to achieve the desired properties. Selecting the appropriate type of alloy steel should be based on working conditions, mechanical stresses, temperature, and environmental factors to ensure maximum service life and performance.

WhatsApp us